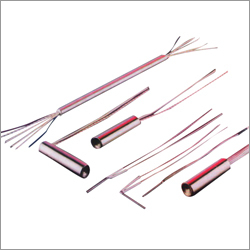

Nozzle Heater

Price 1000 INR/ Unit

Nozzle Heater Specification

- Usage & Applications

- Plastic Injection Molding Machines, Hot Runner Systems, Die Casting Nozzles

- Type

- Nozzle Heater

- Material

- Stainless Steel

- Capacity

- High Thermal Output

- Voltage

- 220 V

- Power

- 250 W

- Power Source

- Electric

- Input Voltage

- 220 V AC

- Output Voltage

- Variable as per design

- Installation Type

- Clamp Mount

- Dimension (L*W*H)

- Customized as per requirement

- Weight (kg)

- 0.25 kg

- Color

- Silver

About Nozzle Heater

We have attained a distinct and dynamic position in the market by providing a high quality array of Nozzle Heater. In order to cater the demands of our clients, this heater is manufactured using the finest quality raw materials and sophisticated technology. The entire range finds wide application in the plastic processing industry and can be availed by our valued clients in customized versions. In order to transfer heat efficiently, our product is checked under variegated parameters. This Nozzle Heater is offered at market leading rates. We also provide for on site repairing of this product.

Features:

- Quick installation

- High strength

- Energy efficient

- Precision Engineering

Customizable Heating Solutions for Industrial Needs

Nozzle Heaters are crafted to fit the precise dimensions specified by the user. The ability to tailor length, width, and height guarantees compatibility with a range of equipment, ensuring optimal thermal transfer and application efficiency. Stainless steel construction further enhances durability and heat retention.

Optimized Performance for Demanding Environments

Designed to deliver high thermal output, this heater maintains stable temperatures in intensive operational settings. Its electric power source and clamp mount installation offer rapid setup and long-term dependability, minimizing maintenance and operational downtimes.

FAQs of Nozzle Heater:

Q: How is the nozzle heater installed in plastic injection molding machines?

A: The nozzle heater utilizes a clamp mount system, enabling secure and straightforward installation onto the desired section of plastic injection molding machines. This makes it suitable for retrofitting or replacing existing heating elements.Q: What benefits does stainless steel construction offer?

A: Stainless steel provides excellent resistance to corrosion, maximizes heat retention, and extends the lifespan of the nozzle heater, ensuring reliable performance in challenging industrial environments.Q: When should I choose a customized dimension for my nozzle heater?

A: Customized dimensions are recommended when your application requires specific sizing to fit unique equipment or to achieve optimal thermal transfer for certain molding or casting processes.Q: Where is the nozzle heater commonly used?

A: Nozzle heaters are widely employed in India within plastic injection molding machines, hot runner systems, and die casting nozzles across manufacturing, supplying, and distributing sectors.Q: What is the process for adjusting the output voltage of the nozzle heater?

A: The output voltage can be customized during design or manufacturing according to the specific thermal requirements of your setup, ensuring versatile and precise temperature control.Q: How does using a nozzle heater improve operational efficiency?

A: The high thermal output and efficient heating capabilities help maintain consistent material flow, reduce cycle times, and minimize production defects, leading to enhanced operational efficiency and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Heaters Category

Coil Heaters

Price 1000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220 V to 240 V

Power Source : Electric

Material : Stainless Steel

Installation Type : Other, Plug In

Electric Cartridge Heaters

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220V

Power Source : Electric

Material : Stainless Steel

Installation Type : Other, Embedded or inserted

Cartridge Heaters

Price 1000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110 V / 230 V

Power Source : Electric

Material : Stainless Steel

Installation Type : Other, Insert Mounted

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free